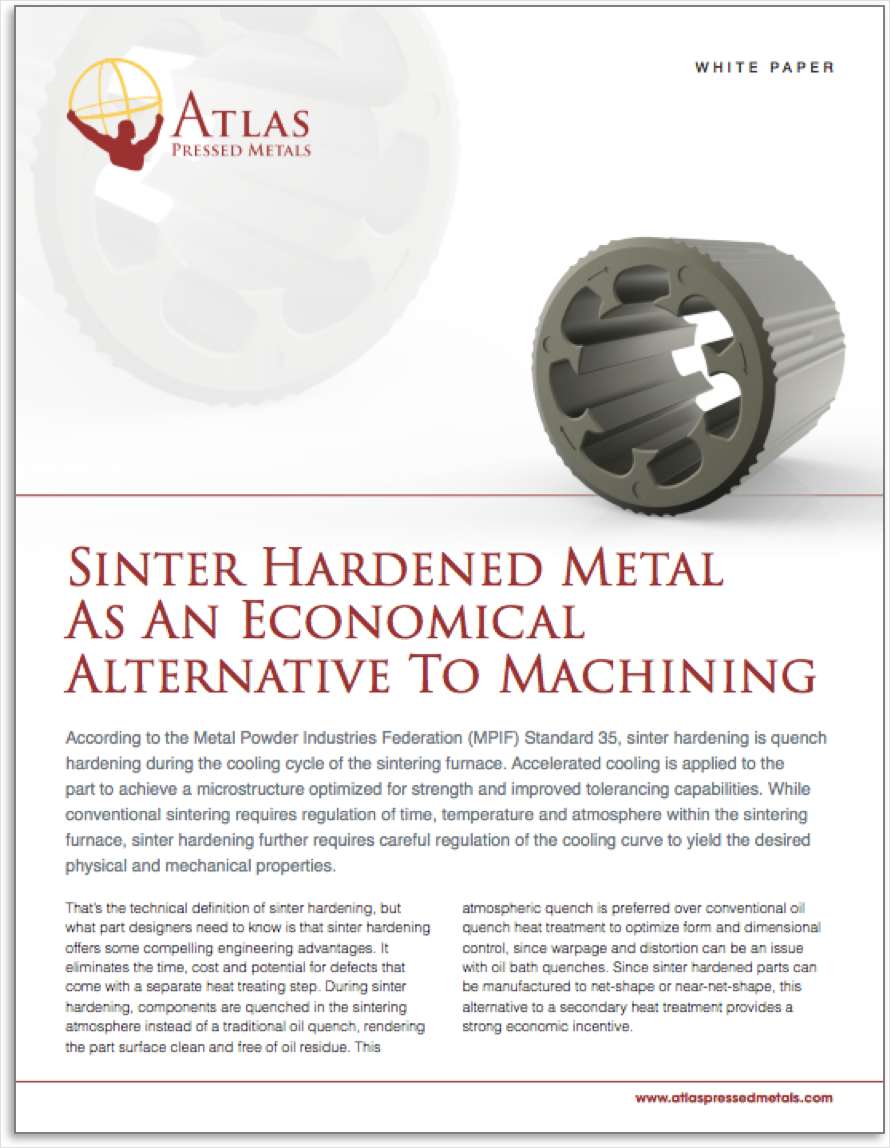

Sinter Hardened Metal As An Economical Alternative to Machining

Atlas Pressed Metals – Precision Parts. Trusted Partners.

New white paper explores benefits of sinter hardening over machining.

Many parts, especially complex parts with tight dimensional requirements, can’t be produced using traditional metal manufacturing methods—at least not in a cost-effective, reliable or repeatable manner. That’s where the sinter hardening process comes in.

This process offers some compelling engineering advantages. For one, sinter hardened parts can be manufactured to net-shape or near-net-shape, making this a cost-effective alternative to heat treating. Sinter hardened parts are also free of contaminants because there’s no residual oil. And finally, it’s an efficient process, saving time, cost and movement versus sourcing a secondary heat treating process.

In this new white paper, Atlas Pressed Metals looks at 3 components manufactured at Atlas that utilize the benefits of sinter hardening. These include:

- Precision gears

- Appliance cams

- Cylindrical housing

Download the white paper now to learn more about sintered hardening.